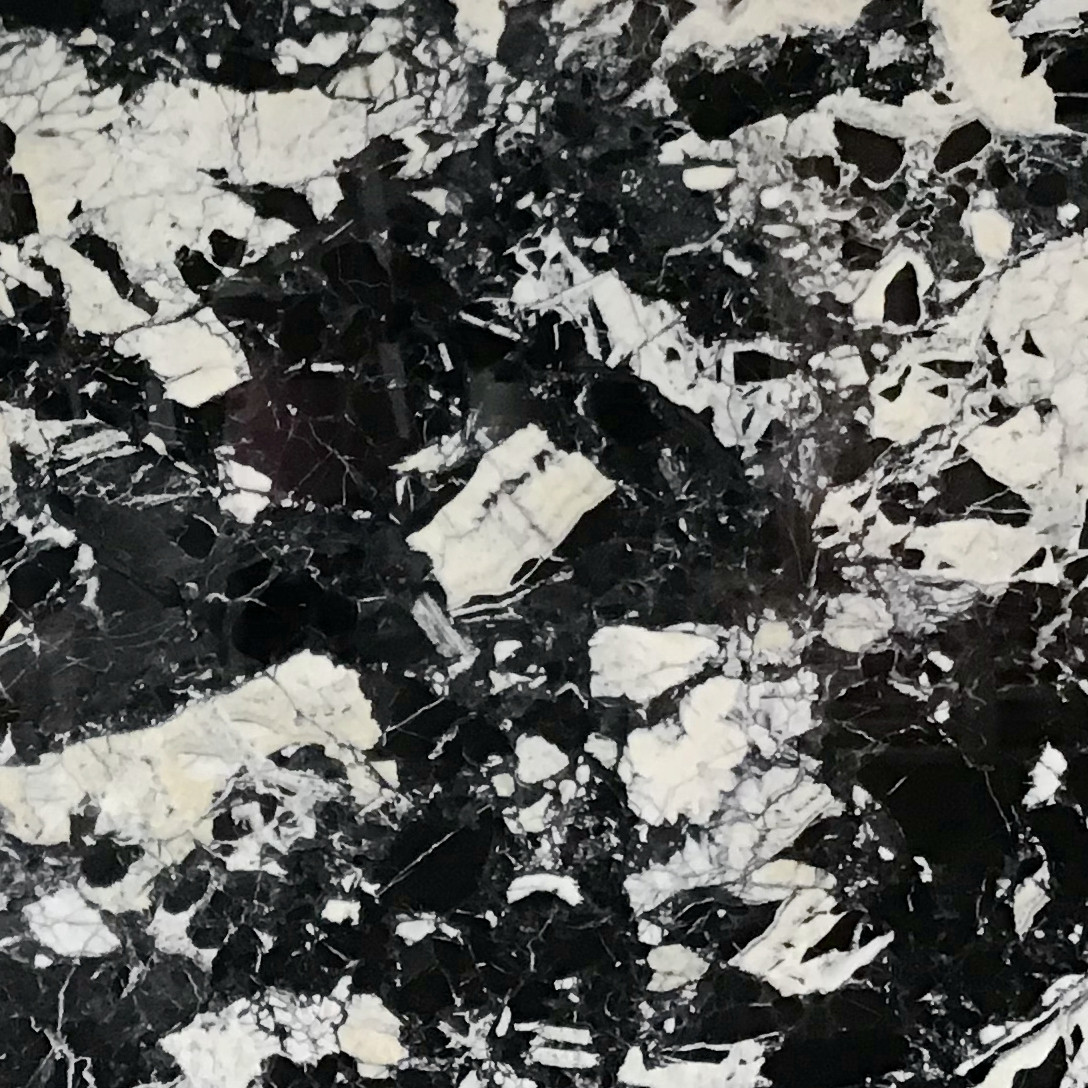

» Classic Hot Sale Grand Antique Narural Black Marble

FAQ:

1. What is the finish processing of your natural stone slabs?

Polished, Honed, grooved, etc.

2. What is your advantages?

We have a strong relationship with the quarry owner, so we can get the first priority to choose the best blocks with the most competitive price. We have sold a lot of good and big size blocks to Italy and India with good feedback.

3. How are your processing and package?

We ICE STONE always pay much attention to quality. Below is our quality control system from the block to slab, and then the loading service.

Firstly, we chose the block from the quarry directly. We can promise each of the blocks which we pick up is the best material. Secondly, we will clean the blocks in our stockyard and do a vacuum coating. After block treatment, all of our blocks will be cut by a gang-saw machine.

Then come to Back Net step. The back net with correct resin could ensure the reinforcement and seal of the slabs. After that, the slab polishing is applied the high quality epoxy resin which is made by Tenax, Italy.

Finally, our quality inspector will follow every step, and strictly touch every piece of slab to ensure the final polishing quality. Once the slab can’t meet our standard, it needs to be re-polished.

Fumigated Packaging & Professional Loading Service

Besides good polishing of the slab, the package is also important. Heat treatment and certificate of fumigation are the essential elements. This could promise the safety of transportation. Finally, all of the bundles would be well positioned and connected to each other according to the exact calculation.